They weigh only 0.25 grams and yet it takes airplanes and ships to bring them where they are needed—communion wafers. New Apostolic congregations can celebrate Holy Communion only if the logistics work.

Neither a choir, nor heating, nor a satellite receiving system, and not even a church building with seating are absolutely necessary. When it comes to the minimum in the way of equipment that a congregation requires, Chief Apostle Jean-Luc lists only three things: ministers, the Divine Service Guide, and Holy Communion.

Ministers are ordained by Apostles and commissioned to work in the congregations by them. The Divine Service Guide is written by Apostles and published by the Chief Apostle. And the communion wafers that are used for Holy Communion are produced—no, not by Apostles—in a wafer bakery, from which 60,000 congregations around the world are supplied. Years of experience and sophisticated logistics make this possible.

The Church runs three wafer bakeries

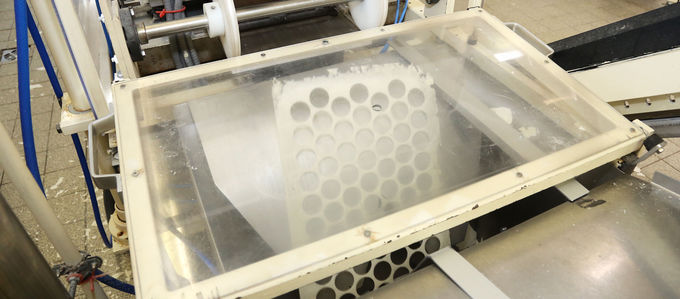

The New Apostolic Church runs wafer bakeries in three locations: one in Bielefeld in Germany, another one in Cape Town in South Africa, and a third one in Lusaka in Zambia. And then there is still a small bakery in India that makes wafers by hand with iron plates and then sprinkles them with red wine. Together the four bakeries produce 200 millions wafers per year. This works out to seven wafers per second—round the clock, seven days a week. The ratio of flour to water is always the same: 1:1.3.

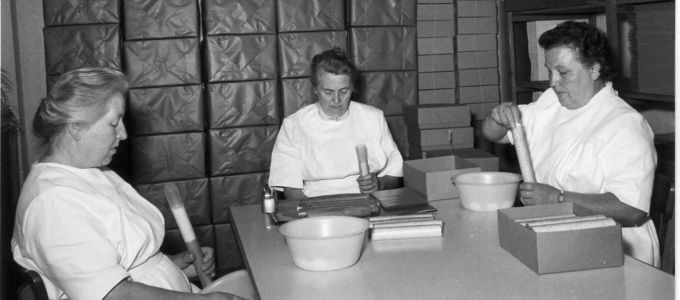

The oldest bakery is in Bielefeld in Germany. It was founded in 1931. The wafer bakery in Cape Town was established in February 2003, the one in Lusaka in March 2012. The reason for these additional bakeries: producing wafers close to where they are needed has made for shorter supply chains and has helped the Church to cut costs. The bakery in Cape Town supplies the districts of South Africa, South East Africa, East Africa, and parts of the Democratic Republic of the Congo (West). Lusaka supplies the congregations in Zambia, Malawi, and Zimbabwe.

Shipping by delivery van, plane, and boat

The bakery in Bielefeld has three full-time staff, one part-time employee, and someone who helps out when needed. More than 60 countries and many thousands of congregations receive their communion wafers from here. The most remote congregations are some 16,000 kilometres away on American Samoa and Fiji in the South Pacific.

After baking the wafers are packaged in small boxes and are readied for shipping. In addition to the actual production, this is an important task of the staff. Up to ten times a month paletts are loaded on to transport vehicles and collected by haulage companies. These are often high-volume orders, such as for the congregations in the Congo. They are air-freighted to Central Africa, from where they are distributed to nearly 80 Apostle districts.

Sometimes the wafers are returned

The communion bakery in Bielefeld also prepares three dozen shipments for traditional parcel delivery. Some countries receive monthly shipments, others two or three shipments a month. “It all depends on the requirements,” Michael Block, the manager of the bakery says, who is a District Evangelist. One shipment is delivered by sea-freight: congregations in Sierra Leone in West Africa receive their communion wafers by ship. In this case, it is the fastest method. Over a hundred million communion wafers leave the company premises in Germany. Some 34,500 are produced by hand for people with gluten intolerance. They are mainly destined for congregations in Europe, Canada, and the USA.

“Every now and then it happens that a package is returned,” District Evangelist Block says. Why, nobody knows. So far, however, no one has refused the delivery of the wafers. Not when first shipped nor in the divine service when the congregation celebrates Holy Communion and enjoys fellowship with Jesus Christ: “Eat and drink! Do this in remembrance of Me,” Jesus said.