The centenary of the communion wafer: a visit to the bakery

Successful recipes are a trade secret—normally. But this is not the case when it comes to the products of the New Apostolic wafer bakery, which are distributed around the world by the billions. Here is a look behind the scenes.

What happened in the past: hygienic concerns and economic necessity displaced the wine chalice from the celebration of Holy Communion starting in 1917. It was only with difficulty at first that the wine came to be applied to the wafer in little drops. The sprinkling apparatuses and waffle irons of the early years eventually developed into the production lines we know today.

From flour to the wine-sprinkled wafer

Forty-nine litres of water and 39 kilograms of Type 405 flour: so reads the basic recipe of the wafer bakery in Bielefeld, Germany—the oldest and largest production facility of the New Apostolic Church. The only other thing that is put into the mixing machine is a little lecithin to make the automatic process run smoothly.

Every 45 minutes, an employee mixes new dough and adds a few more litres of water as needed, depending on the consistency of a given load of flour. The dough then flows through some pipes from the adjacent room over to the baking machine, which dominates the actual production room.

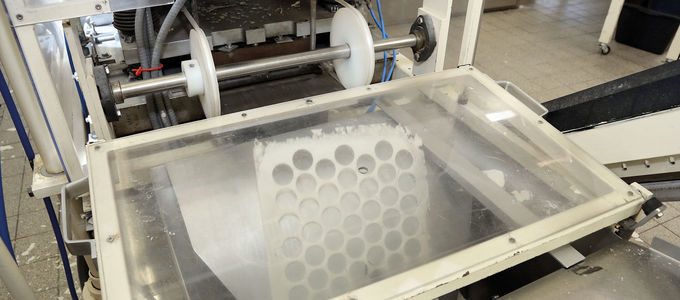

The large machine has 31 “waffle irons”, into which the dough now flows. Each sheet then runs through the oven for about one minute before the oven opens again and a burst of air pushes the baked sheet, which weighs less than 20 grams, onto the conveyor belt.

When they are fresh out of the oven, the baked sheets are quite dry and brittle. This means that further processing would cause some crumbling. So it is that the sheets are sent to the conditioner next. After being exposed to steam for five minutes, the wafer sheets are flexible enough to continue their journey undamaged.

So far, so normal. It is only in the sprinkler that the wafers receive their special New Apostolic character, namely three drops of wine—at present a “blue Zweigelt”, on account of its powerful colour. Each wafer receives about one square millimetre of thickened wine, which has been boiling for twelve hours already and has thus lost most of its alcohol content.

The second-last stop in the production process serves to stamp out the wafers: each baking sheet yields 73 round wafers. The remaining dough around the wafers is shredded and disposed of in an environmentally friendly way—in either a composting facility or a bio-gas plant.

All that remains now is for the wafers to make their way to the packing station: some 1,600 wafers are deposited into each box. And since these are not counted, but rather weighed, there are sometimes more and sometimes less—all depending on the weather situation and humidity in the air.

The four-plus-one-day-week

The wafer bakery in Bielefeld operates for about ten hours each day—four days a week. The Friday is devoted to cleaning and repairs. This also saves operating costs. Three full-time and several part-time workers ensure that the whole process goes smoothly. At least two employees have to be there in order to keep production running.

Every two weeks, the bakery takes delivery of around four tons of flour. This suffices for eight to ten workdays. In this way, over 100 million wafers are produced each year. These are distributed to more than 60,000 congregations around the world. Distribution is not always easy. And these wafers are not the only things baked in Bielefeld. But those are two completely different stories…